Extras for our gas springs

Brimotech offers opportunities to expand gas springs

Since our production largely consists of developing and manufacturing specific gas springs, there are very many possibilities to produce the gas springs entirely to the desired specification or to add various features as options. All with the aim of optimizing the gas spring for the respective application. Below is an overview of some of these possibilities.

Special options gas springs

Dynamic damping

A specially shaped groove in the cylinder ensures uniform damping. We can thus install the gas spring in any position while maintaining damping. Even for horizontal applications such as doors, we can achieve the right type of dynamic

damping. With this technique, the gas spring always has damping regardless of the installation position. We can produce almost all our gas springs in a dynamic damping version.

Friction

Normally one wants a gas spring with as little friction as possible, however for certain applications a certain high internal friction is desired. We adjust the internal friction to fully match the gas spring to your application.

Also this we can deliver customer specific.

Specific damping(s)

Based on your requirements, we develop the desired speed and delay, both on the input and output stroke.

FDA approved oil

It is possible to provide your gas spring with FDA approved oil. This is especially interesting for the food processing industry.

Viton seals

Very suitable for high temperatures and/or aggressive environments. When the gas spring is exposed to cleaning agents or higher temperatures, we can equip the gas spring with Viton seals. This is standard on our 316 stainless steel

gas springs.

Protection tube

Additional protection of the piston rod from mechanical damage.

Dust cap

Additional protection cap for the seal. Can also be used as a scraper.

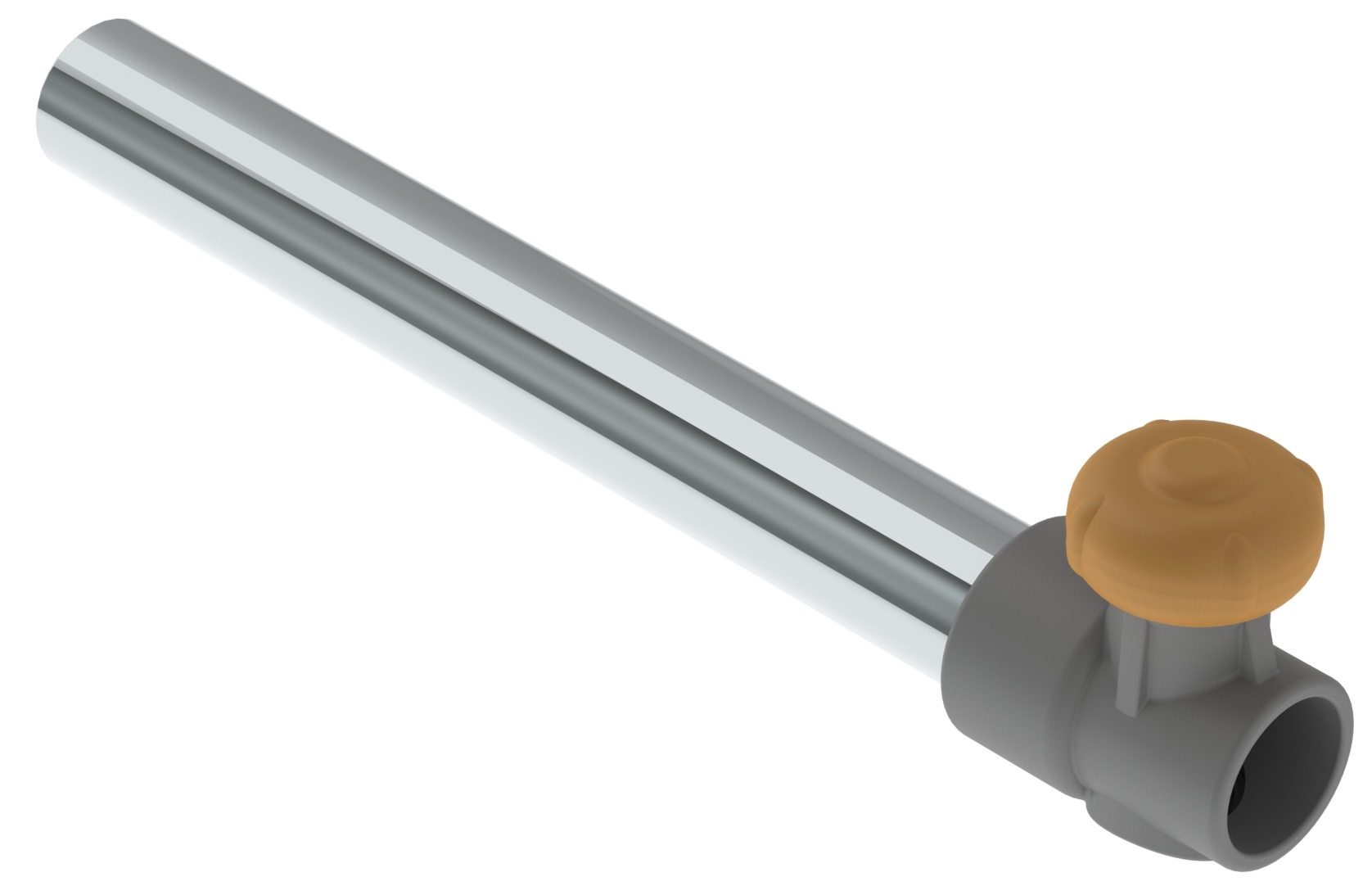

Valve

Especially for prototypes a valve is very useful, adjusting the force we can do for you in Lelystad on our own developed digital machines. Both our steel and stainless steel 316 gas springs can be fitted with this valve.

Colours

If desired we can deliver gas springs in different colours. Our standard colours are RAL 9005 and RAL 9006 (black and ALU/white). Various other colours are available on request.

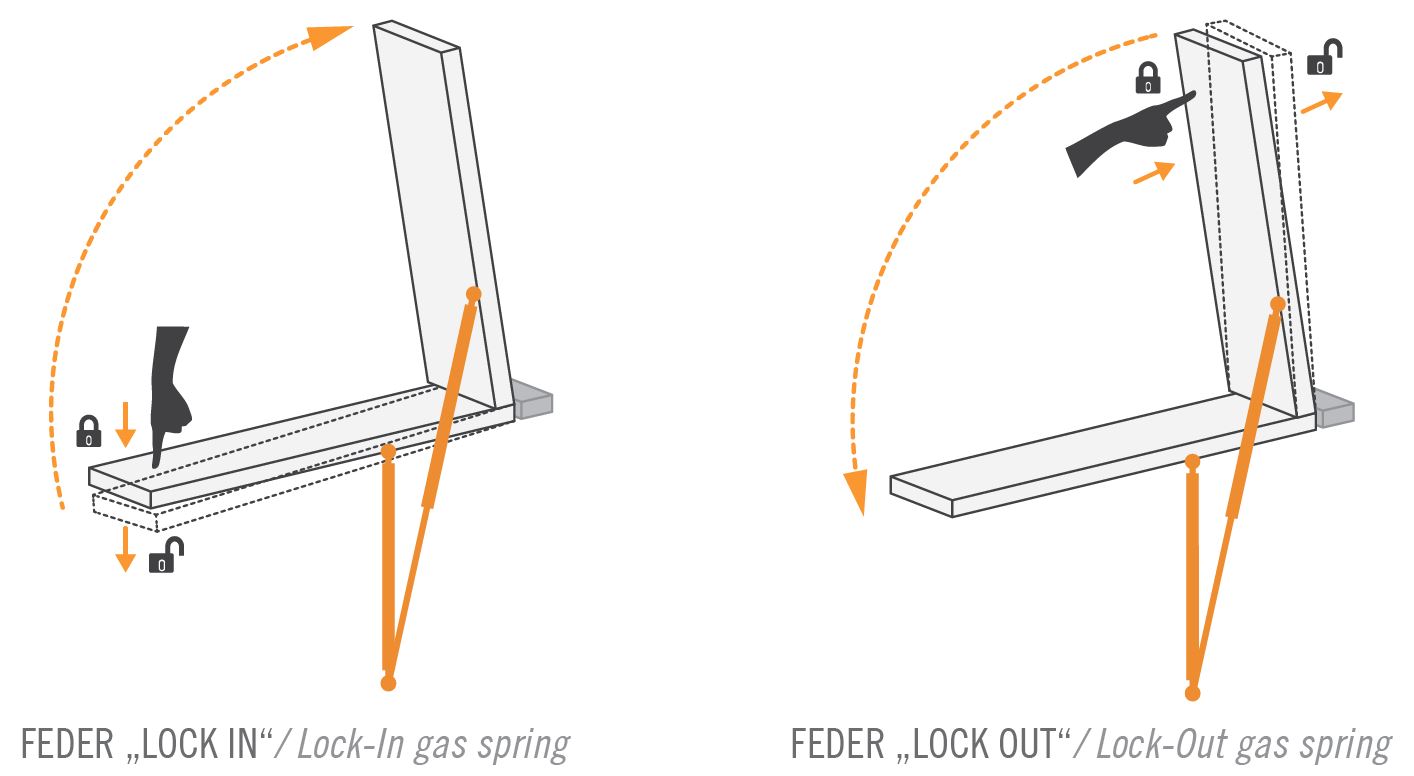

Lock in | Lock out

An internal mechanism that locks the gas spring when fully extended or retracted. By means of a blocking system completely concealed in the cylinder, the gas spring/damper can automatically lock in the fully extended or fully extended position. A simple push on the gas spring will instantly unlock it.

Rod Lock

Mechanical locking of the gas spring in any position. This lock is designed to lock the gas spring in any position and is available only in stainless steel 316 for the diameters Ø15/06 and Ø19/08.

VB Lock

Mechanical blocking when the gas spring is fully extended. This blocking system is designed to mechanically block the gas spring in a fully extended position. Available in both steel and stainless steel 316 for the diameters Ø19/08 and Ø22/10 and applicable to almost all (standard) gas springs.

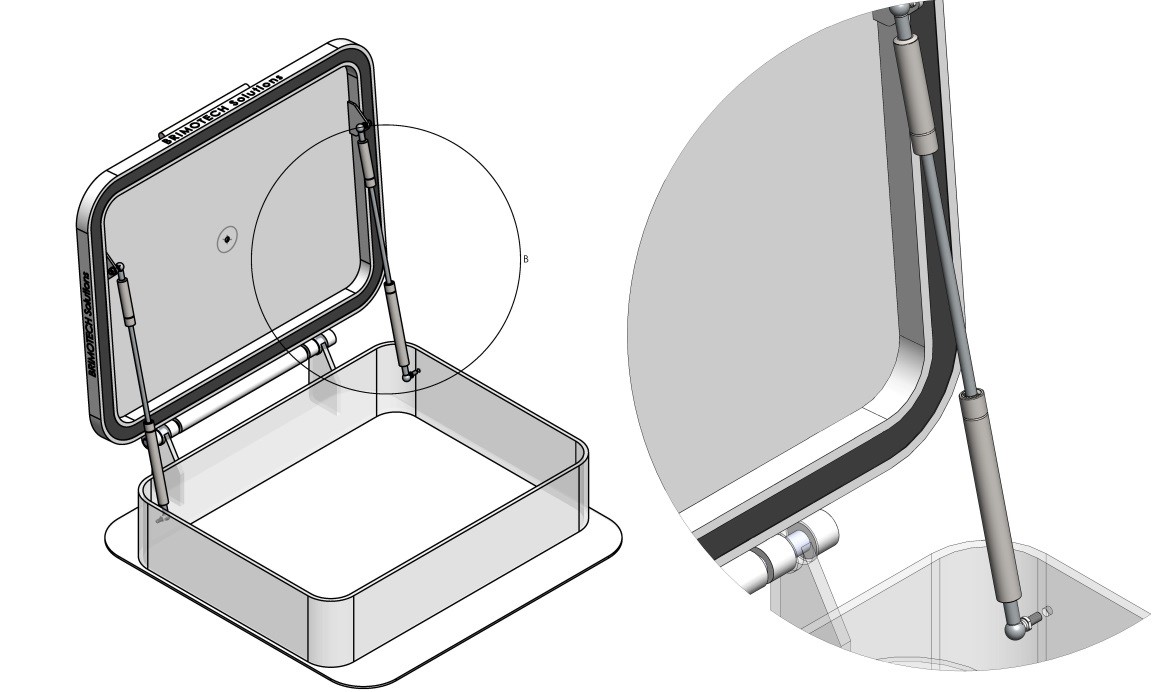

Tandem gas springs

The tandem gas springs are used with relatively large or heavy hatches and valves. Because there are two separate cylinders, these tandem gas springs can deliver two different forces. A heavy hatch will require a much larger force when opening than when closing the hatch. This is why tandem gas springs for hatches are ideal.

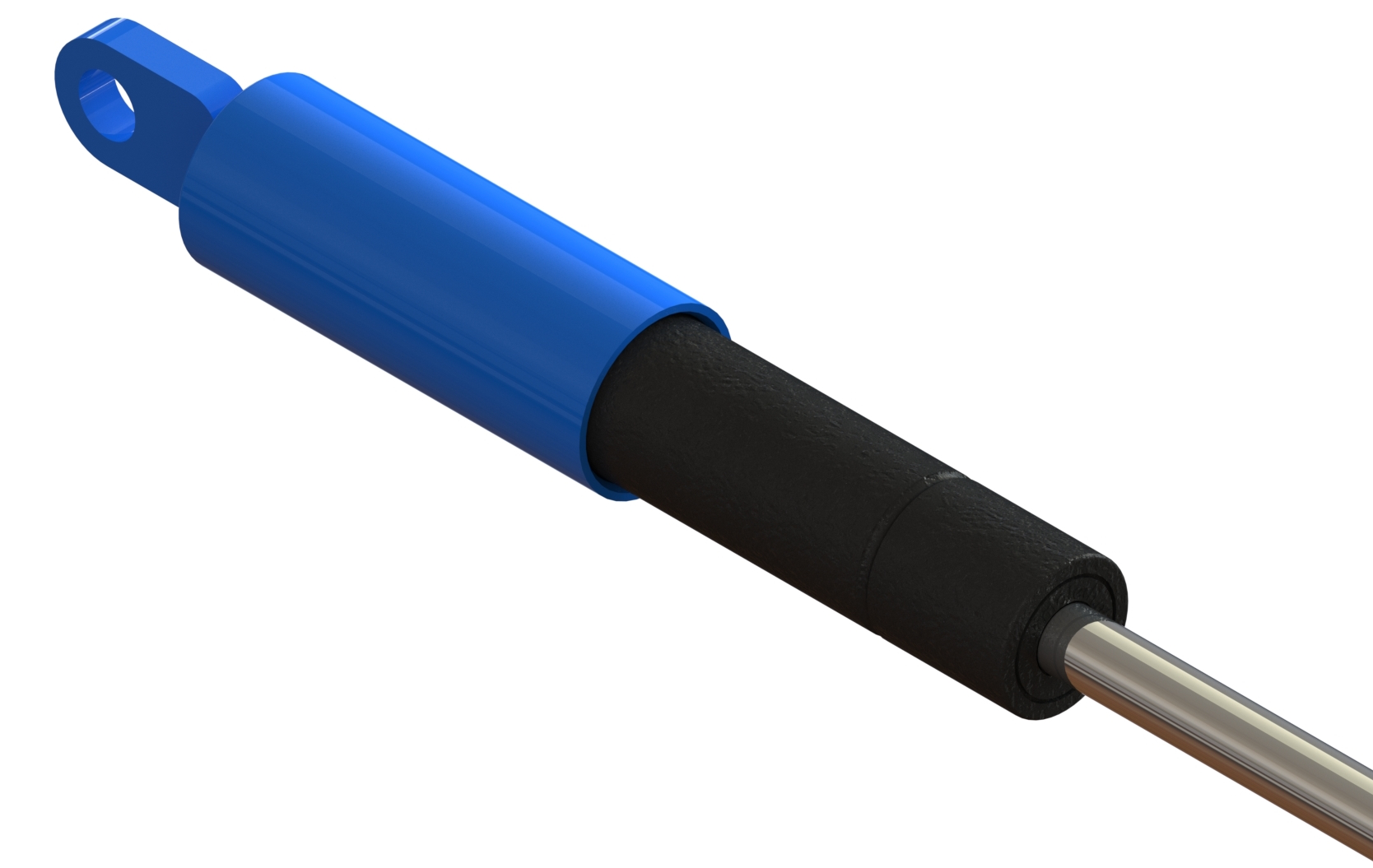

Anti Tear

The Anti Tear gas spring is a clever invention on protecting the gas spring on tensile loads. It consists of a gas spring whose cylinder has no connection. This gas spring can be inserted into the appropriate Anti Tear cylinder which allows the gas spring to be loaded only on compression. With a movement of the application greater than the maximum length of the gas spring, the Anti Tear cylinder will only shift on the gas spring so the gas spring can never be loaded on tension. In addition, there are situations where the application as a safety must be able to make a larger opening angle than can be realized with the gas spring alone.

Hybride

We have the possibility of producing so-called hybrid gas springs. That is, a steel cylinder and a stainless steel 316 piston rod or vice versa. The right combination of materials depends on the final function of this gas spring.